Forsyths are proud to have successfully completed the installation of a new Germination and Kilning Vessel (GKV 10) at Simpsons Malt in Berwick-upon-Tweed; a key project that aimed to increase onsite malting capacity by approximately 15,000 tonnes per year.

The vessel, supplied by Bühler, measured 36m in diameter with 8m high side walls and a domed roof. Forsyths managed and executed a comprehensive installation scope, including:

Main Vessel Installation

- The vessel walls and roof were partially pre-assembled in a storage shed before being lifted into position.

- Wall sections were internally clad and seal-welded, then lifted into position and set with a jig frame to ensure millimetre accuracy.

- A custom central scaffold enabled safe and accurate installation of the 28 stainless steel petal roof sheets, which were welded internally and externally to ensure an airtight seal was maintained.

Internal Floor Construction

- Precision was critical: the steel plate flooring was levelled within 2mm tolerances across the entire floor deck.

- Segmented wedge wire panels were installed with equal spacing and carefully tack-welded to prevent distortion.

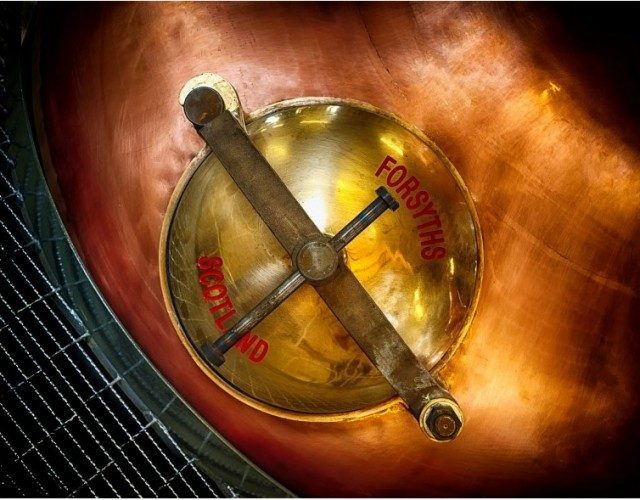

Install of Loading/Unloading Arm

- A 16-tonne loading/unloading arm was lifted through an open roof section and secured to the internal tracking system.

Kilning Detailed Design, Fabrication and Insulation

- Forsyths carried out detailed design, fabrication and installation of the Kilning element of the vessel which had to be connected to the existing system.

- Thanks to careful planning and expert execution during a brief shutdown window, we seamlessly integrated the new vessel with the existing kiln system – ensuring zero disruption to the ongoing production.

Final Fit-Out and Finishes

- Forsyths installed all internal ducting and germination fans.

- Internal vessel walls were fully clad and seal welded in stainless steel.

- We managed the full insulation and cladding of the external structure, maintaining high quality and safety controls with two of our key subcontractors Curtis Insulation and Simmers Contracts.

A key success factor was ensuring our personnel were trained and certified to manage lifting operations utilising a tower crane safely and efficiently on-site.

Huge credit given to our dedicated team and project partners for delivering a complex, high-precision build.